A CRAFT FINE-TUNED

Clay is the stuff of our livelihood.

Since 1971, we have been making pots together at our Leetown Studio on Owls Nest Lane.

Learn more below about our creative process and the history behind our methods.

Since 1971, we have been making pots together at our Leetown Studio on Owls Nest Lane.

Learn more below about our creative process and the history behind our methods.

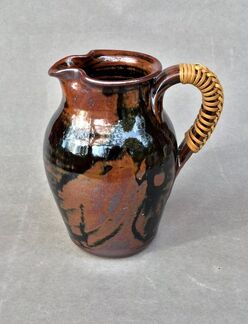

POTS TO USEMany of our pots are functional, happy in the kitchen or on the table. Our pots feel good to the hand as well as to the eye. A particular pot “fits” you, and it may take years to develop one’s own style. Ren laughs when he says, “Our pots are nearly perfect and almost alike!”

Our workbooks have sketches for dozens of shapes, from large platters to small cups, and detailed specs for glazes and brushwork. |

A BALANCING ACTIt seems a contradiction, but we like the freedom that total responsibility for our pottery provides for us. We keep our functional ware even and consistent. If we want to experiment with glazes, or try different clays, we do it. Being creative is a balancing act between the spirit and necessity.

Creation and chemistry are constant themes in our life. The transformation that stoneware clays sustain at cone 10 (2300 degrees Fahrenheit) is a source of endless wonder. “Once you accept that it’s a miracle,” says Ren, “everything else makes sense.” |

THE CLAY

|

Terra Cotta

At Sycamore Pottery we use several different clays. Terra Cotta give us the chance to add colorful glazes, experiment with new designs, and fire quickly in the electric kilns. |

Stoneware Clay

Stoneware clay, a high-fire clay, is good for making dinnerware and pots to use in the kitchen. Our wheel thrown stoneware pots are known for the quality of workmanship and design. |

Porcelain

Porcelain is a refined white clay that loves a celadon glaze, and adds a refined elegant quality to our studio work. |

THE KILNS

|

Stoneware Downdraft Kiln

Our studio contains several kilns, the largest is an 80-cubic foot down draft, flat roof built on small-gauge railroad track so the car on which the pots are stacked can be easily pushed in and out by hand for loading and firing. Salt Kiln

We also have a kiln specifically designed for firing salt-glazed pots, an old process used in early America. Salt firing of stoneware clays is a 17th and 18th century means of glazing pots with the introduction of salt into the kiln; the salt volatizes and becomes one with the clay. Electric Kilns

We have two electric kilns used for firing terra cotta clays. |